Anaerobic digester plants are an excellent choice for producing biogas and methane recovery from wet organic waste. The process has been around for more than 40 years. Although well proven, many operators suffer with disposal of its residues (called digestate). The anaerobic process does not reduce the amount of volume fed into the system. Thus, 100% of organic material mixed with a lot of water, produces very large quantities of digestate, typically consisting of only 8% dry solids.

The digestate has good fertilising properties. However the spreading of it on land is restricted by local regulations. It requires a modified sludge spreader and that introduces other logistics challenges. Often a waste management license is required to spread digestate to land. These are some of the causes limiting the installation of anaerobic digester plants.

Organic sludge and digestate have good soil fertilising properties, but strict regulatory controls restrict its use. Our sludge dryer solution is developed to change this.

Compact, economical and flexible

Most sludge dryers come with a very high capital cost or they consume large amounts of power. Both causing the final solution not to be economically viable for the investor.

Our solution is developed to use as little power as possible and designed to give you a return on investment in around three years. Thereafter you will be generating a profitable income.

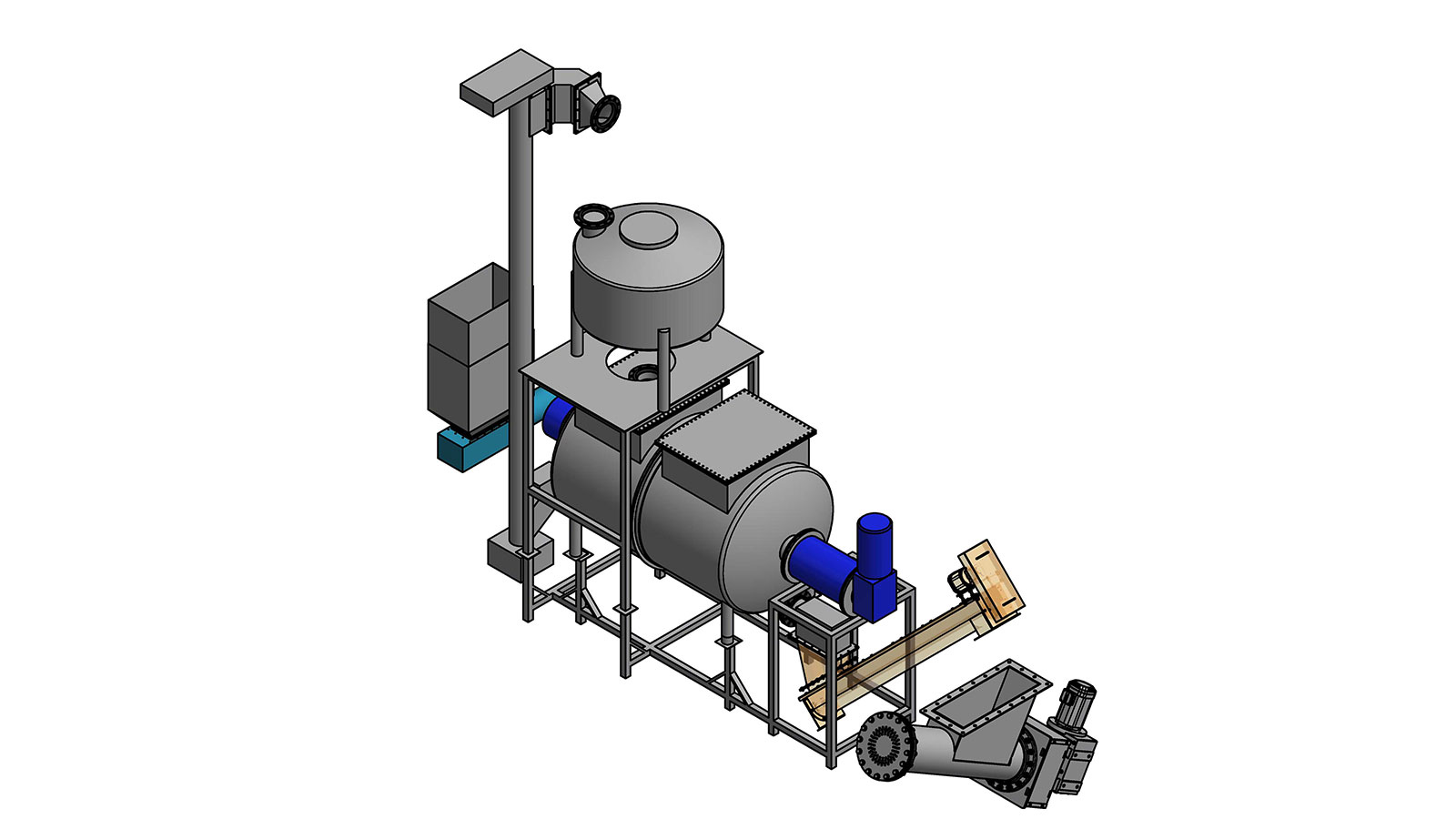

We use a preheater, a rotary dryer and recycled heat. We set up an affordable solution based on your resources and requirements. The end product will be a granulated 85% dry solid, usable as slow release fertiliser.

To prove that we believe in the value of the end product, we will buy it from you, giving you an immediate return by making savings from storage, sludge transportation and income from fertiliser sales.

Our solution gives you an immediate return by making savings on sludge storage and transportation, and provides an income from the granular fertiliser.

Quality finished product

Initially we will treat the granules as waste. As we hold a waste carrier license, we will give you complete traceability of the material. During this process, we will work towards ensuring the material is reclassified as ‘non-waste’, by analysing samples and showing scientific evidence of the material.The test we do includes a material stability test and pathogen counts. It will be integrated as part of our solution.

If we find the digestate contains undigested material, then we will configure our dryer with our digester to complete the digestion process.

We work towards DEFRA and Environmental Agency for ABPR site approval. We carry out regular chemical analysis tests on fertiliser output in order to ensure that our process continuously meets relevant regulations.

Where can ecoDRYER be used?

Some of the places the "ecoDRYER" can be used are: Anaerobic Plants, Sewerage Treatment, Food Manufacturers, Ethanol and Bio Fuel Plants.